SUPPORT

DRIER

Receiver/driers, also sometimes called “filter/driers” or “receiver/dehydrators”, look like small metal cans with an inlet and outlet. They are only used in A/C systems that use expansion valves

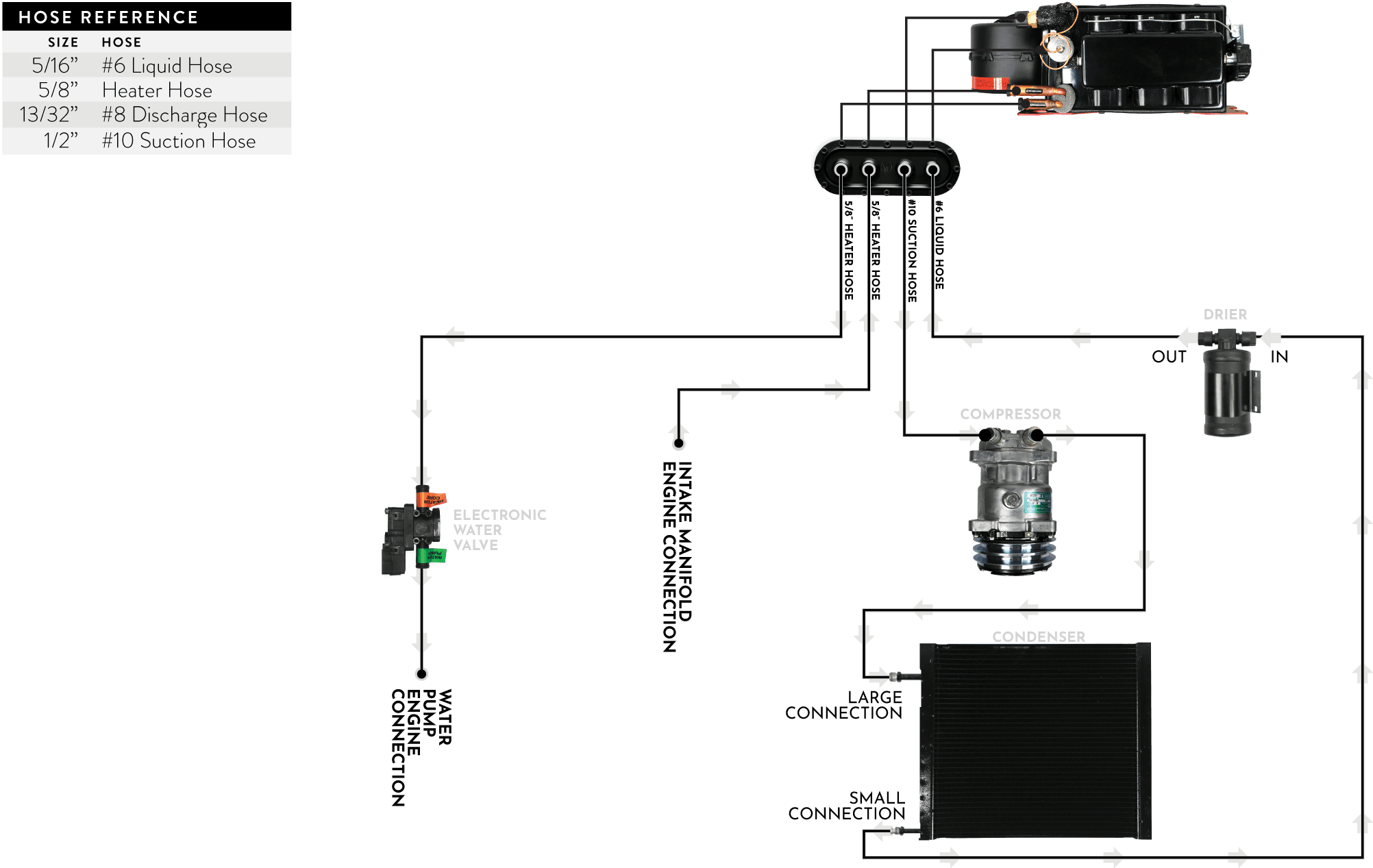

Receiver/driers are located in the high-pressure section of the system, usually in the plumbing between the condenser outlet and the expansion valve inlet, although some may be connected directly to the condenser.

The filter drier acts as an article filter, refrigerant storage container and most importantly, moisture absorber.

Moisture, temperature and R134a causes hydrofluoric and hydrochloric acid. The silica gel beads located in the FDR absorb small quantities of moisture thus preventing acid establishment.

R134a filter driers DO NOT use sight glass for charging. This is because at approximately 700º C refrigerant temperature the PAG oil will foam, giving a false impression of low gas charge.

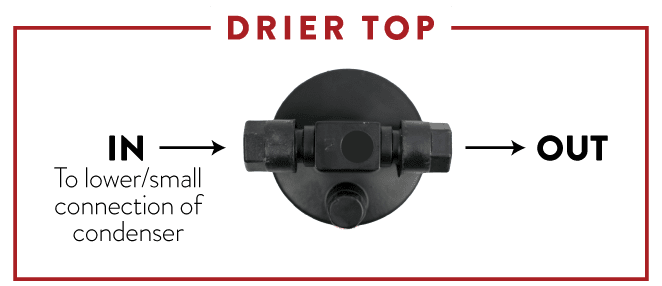

Note: Ensure the connection indicated with the word “IN” is connected to the condenser outlet.

Important: Never use an R12 FDR on a R134a system.

RECEIVERS/DRIERS SERVE THREE VERY IMPORTANT FUNCTIONS:

-

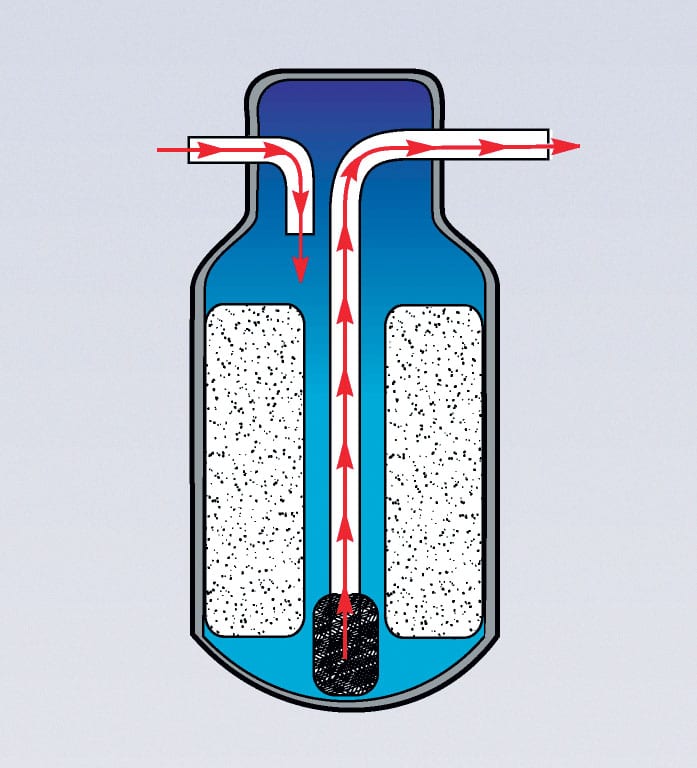

They act as a temporary storage containers for oil and refrigerant when neither are needed for system operation (such as during periods of low cooling demand). This is the “receiver” function of the receiver/drier.

-

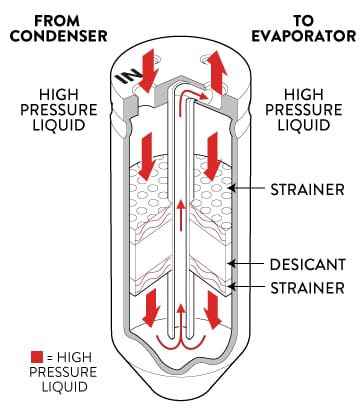

Most receiver/driers contain a filter that can trap debris that may be inside the A/C system.

-

Receiver/driers contain a material called desiccant. The desiccant is used to absorb moisture (water) that may have gotten inside the A/C system during manufacture, assembly or service. Moisture can get into the A/C components from humidity in the air. This is the “drier” function of the receiver/drier.

CAUTION:

Damage can occur if there’s excessive moisture inside an A/C system. It can cause corrosion, as well as possibly degrade the performance of the compressor’s lubricating oil.

The receiver/drier should be replaced any time the system is opened for service, and most compressor warranties require it. The desiccant is only capable of absorbing a certain amount of moisture, and when the inside of the system and/or the receiver/drier are exposed to the atmosphere, the desiccant can become very quickly saturated from humidity in the air. If this occurs, the desiccant is no longer effective, and will not provide future protection.

Additionally, the filter inside the receiver/drier could be restricted by debris that may have been inside the system. This could diminish refrigerant and oil flow.

DRIER MOUNTING

Keep in mind the following when mounting the drier:

• The drier will be inserted into the drier bracket. It’s basically a sleeve for the drier.

• Drier mounts vertical with connections on top. Threaded connection labeled “IN” will connect to the lower connection of the condenser.

• Drier needs to be mounted in a location where hoses can reach. Keep in mind refrigerant hoses from condenser must connect to it.

• Do not leave drier open longer than a couple minutes. Drier will have to be replaced if you do so.

• When removing caps, pressure will release.